Build Day: Intake-1 Iterations 2, 3 , and 4

sort

|

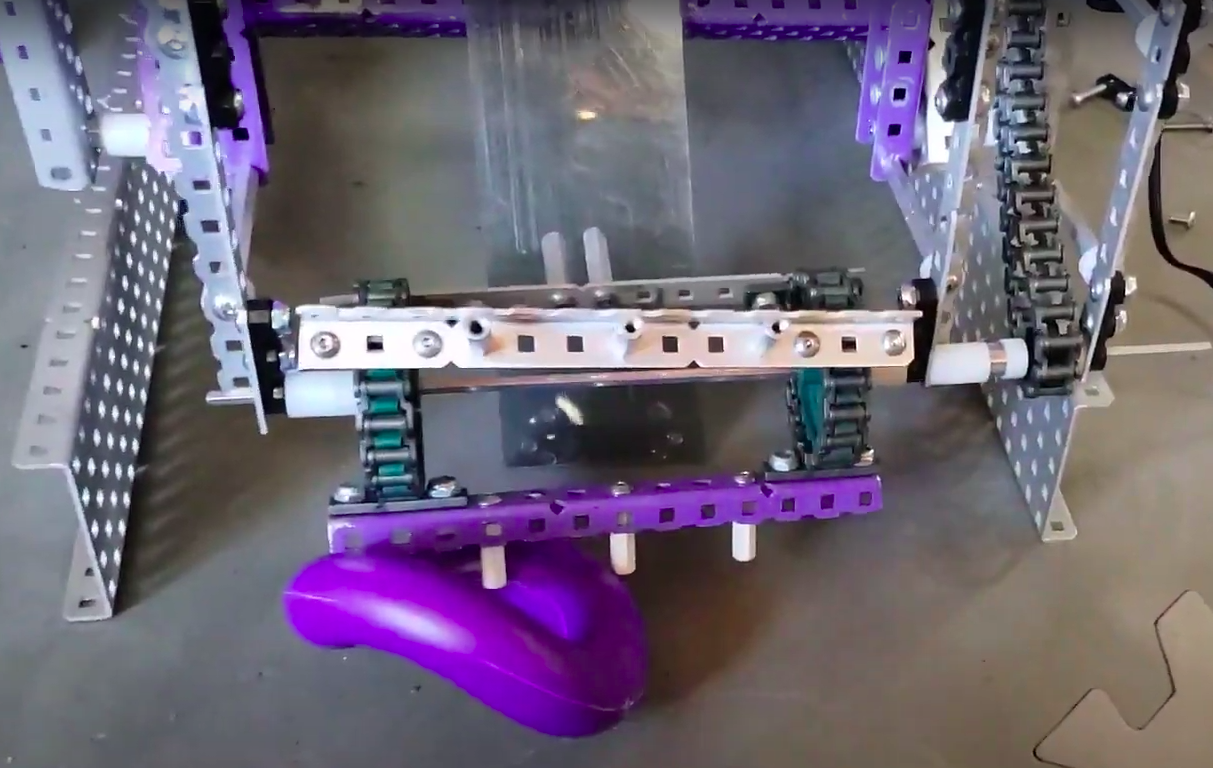

Intake-1.2DesignWhile it might be hard to funnel Rings on standoffs as discussed in yesterday’s reflection, it still might work to intake a wider range of Rings then funnel at the very end as we shoot onto the Mobile Goal Branches, so we should still consider using standoffs, but in a wider configuration. To make this wider standoff intake with our limited chain attachment links, we used two sprockets connected with c-channels. CreateThis was easy to build, just replacing the rubber band roller:

TestWhen testing this design, we used a lexan piece instead of metal. This version worked exactly as expected: as fast as the standoff intakes but with a little wider range. ReflectWhile these intakes work well, the fact that the standoffs are rigid is problematic. When the intakes are moving fast, the standoffs slam into Rings so hard that the lift shakes when they are moving fast. This is a problem because:

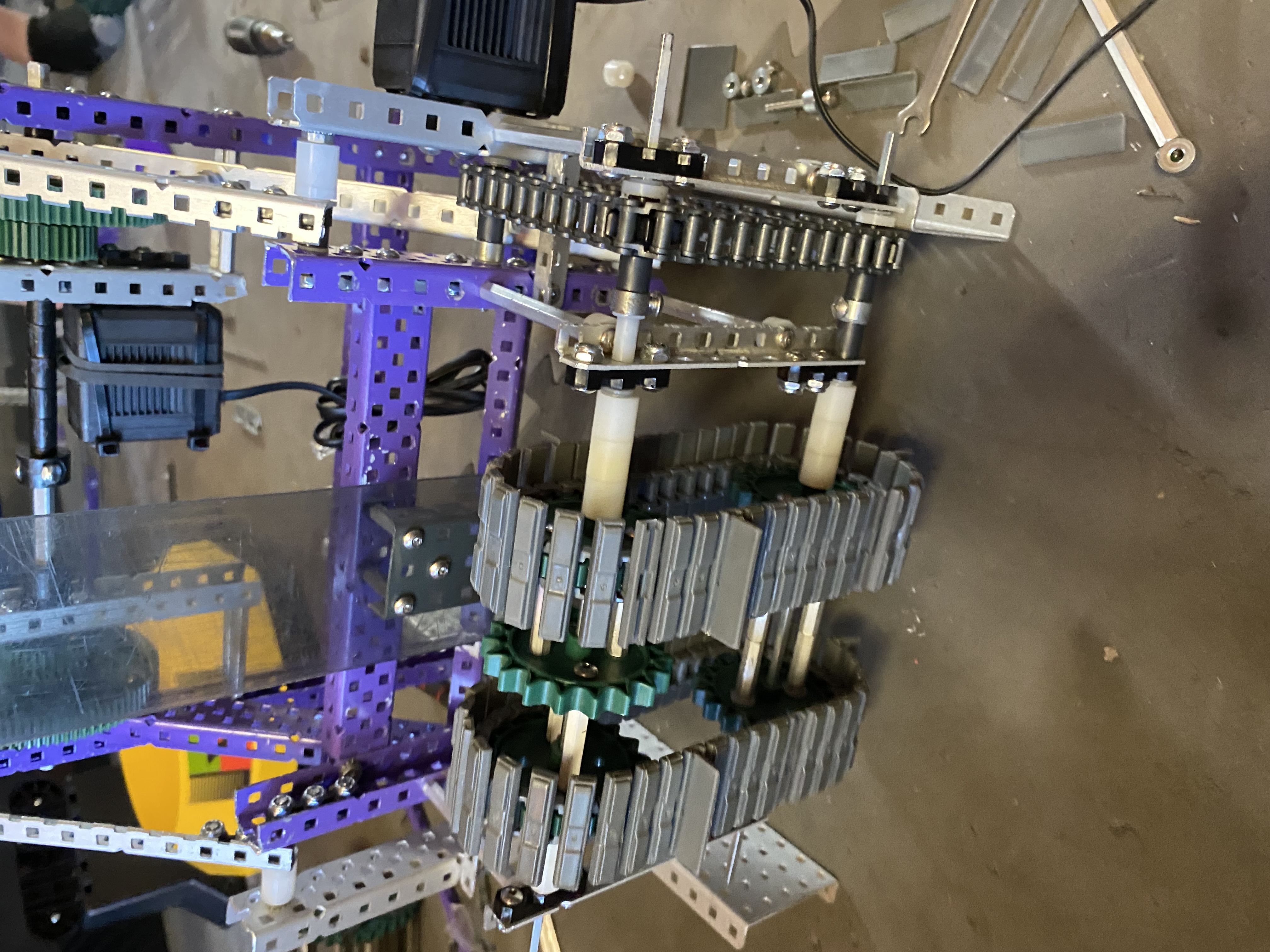

A standoff intake could potentially work well if we cannot find a something that works faster, but we should continue to investigate other solutions to problems. Intake-1.3DesignThe purpose of using standoffs was to have the intake reach into the Rings. Another way we could do this is with tank tread flaps. We will try a design similar to Intake-1.2, but with flaps instead of standoffs. To make it easier to create the conveyor, we are going to separate the two sprockets so the conveyor can connect in between them on the same shaft. CreateWe attached the sprockets to each other with standoffs for more rigidity. Additionally, we put in the next shaft up to test how well the intake would lift the Rings.

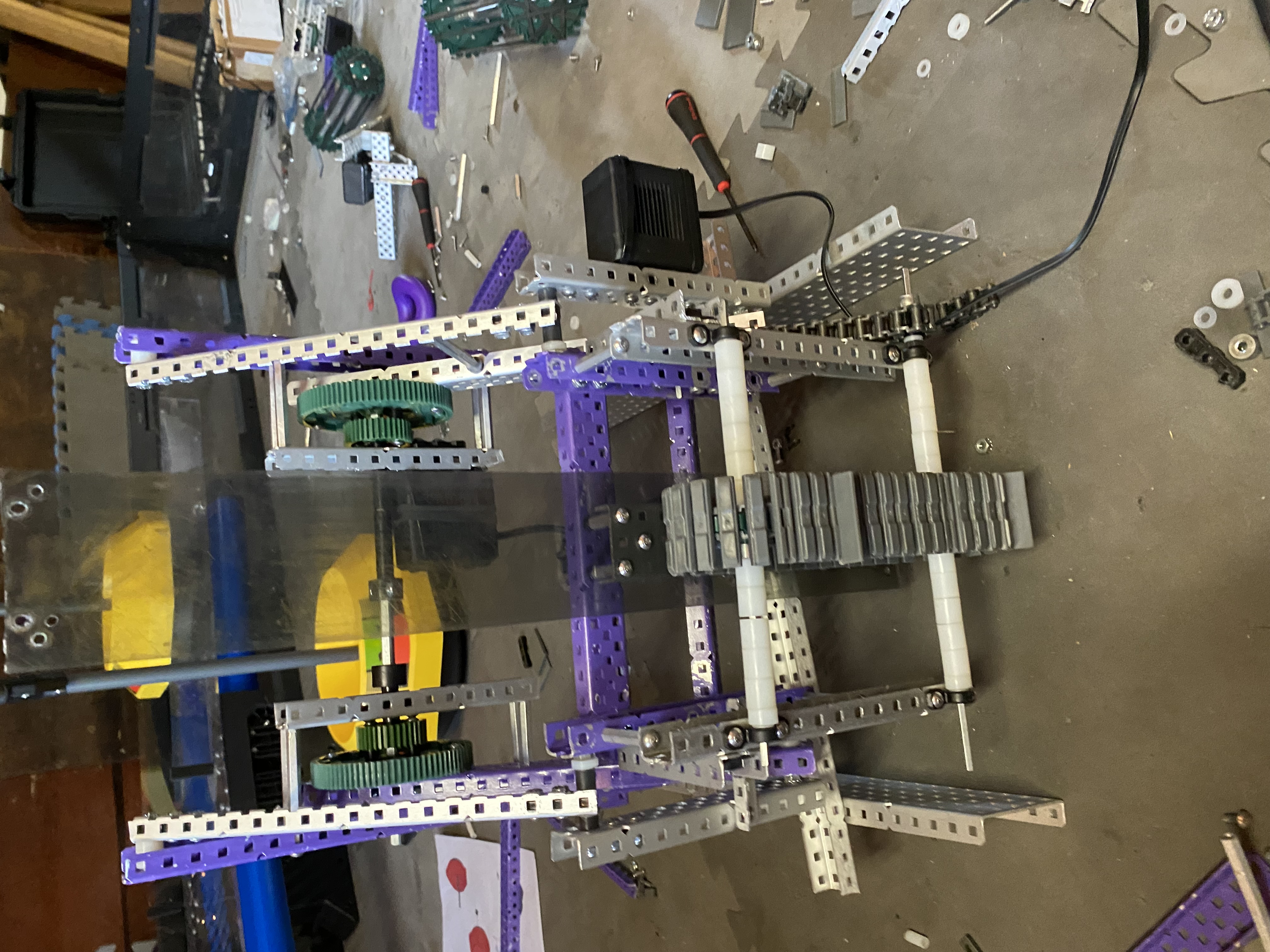

TestTesting is now easier with the back wall and the second sprocket. Compared to Intake-1.2, it seems to be both as good at lifting Rings and as fast. However, it cannot pick up Rings in the center. ReflectOf all the solutions tested so far, this is definitely the best one. However, it still is not good enough, because we should be able to intake Rings in the center, because it is easier for driving and would be easier to make an external funnel. Intake-1.4DesignTo be able to pick up Rings in the middle, we need rollers in the middle, and to do that, we cannot have the conveyor start on the second shaft. Instead, we are going to attach the bottom of the second stage higher. Otherwise, this will be a simple change. CreateBecause we now know that we are not going to use a rubber band roller, we made the front bars on the lift each 0.5” closer to the middle so we do not need as long of shafts in the middle, which makes them more sturdy.

TestThis version works just like the last one, but successfully pics up Rings in the center. ReflectLike all designs, this could be better, especially at intaking from a wider range, but at this point it works well enough. Now, it is more important to get the rest of the robot working. |